The grain size of a polycrystalline aggregate plays a key role in controlling the mechanical behaviour of the material. It is one of the factors determining the creep mechanism, the kinetics of diffusional processes and the ability of grain boundaries to slide. In general, fine-grained materials deform by grain-size sensitive mechanisms at high temperatures. At similar conditions of stress and temperature such mechanisms are generally faster than dislocation creep. For an understanding of mantle rheology, it is therefore essential to understand the kinetics of grain growth in polyphase aggregates under upper mantle conditions. So far grain growth has only been studied in single phase end-members (e.g. olivine) and there are no reports of the simultaneous grain growth of phases in olivine-enstatite mixtures, nor of their microstructural evolution.

Pure Mg end-member olivine-enstatite mixtures have been synthesised using a sol-gel processing technique (McDonnell 1997, Geologica Ultraiectina 152). Two types of fine-grained (~1 µm) samples, with 25 vol% and 50 vol% enstatite respectively, have been synthesised. These mixtures were first sintered at 1400°C and ambient pressure with the aim of producing starting materials for the high-pressure grain-growth experiments. The latter were performed in a piston cylinder apparatus at 20 kbar and temperatures between 1200 and 1400°C. Solid-medium talc-pyrex cells, containing two welded Pt capsules (containing the two starting materials) were used as the pressure medium. Orientation-contrast imaging in the scanning electron microscope (SEM) combined with computer-aided image processing and analysis have been used to characterise the microstructures and to determine the grain size of the samples.

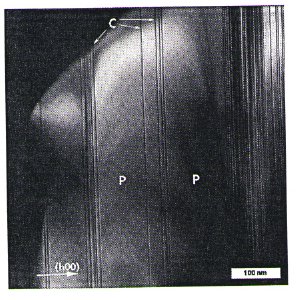

The initial sintering resulted in very fine-grained (1-1.5 µm) samples in which grains of the two phases were evenly dispersed. The sintering conditions were within the stability field of protoenstatite. Upon quenching only part of the protoenstatite (~25 %) transformed to the low clinoenstatite polymorph. This is in contrast to the complete transition of protoenstatite to low clinoenstatite, which is normally observed at ambient conditions, i.e. protoenstatite is normally found to be unquenchable. Using powder X-ray diffraction analytical techniques together with high-resolution transmission electron microscopy (HRTEM), we have solved the structure of protoenstatite in the presence of forsterite and characterised the microstructure (Fig. 3.1-7). Due to the beam sensitivity of the enstatite, HRTEM was difficult but not impossible. The orthorhombic structure of the protoenstatite was confirmed and thin lamellae, which appear to have monoclinic symmetry, were identified (Fig. 3.1-7b). The TEM images are consistent with the powder X-ray diffraction results.

|

|

Fig. 3.1-7: Noise filtered TEM micrographs (a) Dark field image showing thick regions of protoenstatite (P) alternating with clinoenstatite lamellae. The latter appear as dark lines (C) and are oriented parallel to (100). (b) HRTEM image showing details of the proto- and clinoenstatite structures. Note that this image is best viewed at a glancing angle. |

|

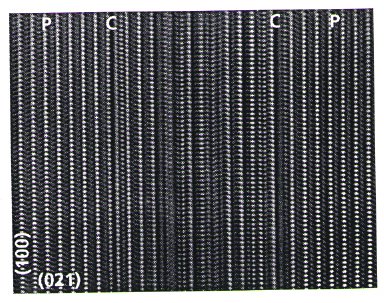

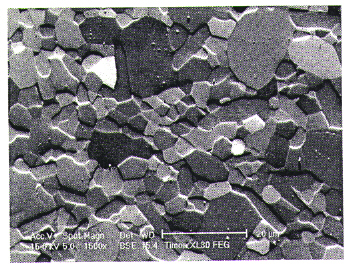

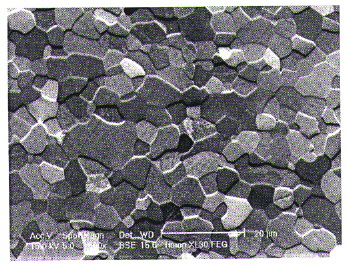

Both at 1 bar and at 20 kbar, the olivine-enstatite mixtures grow orders of magnitude more slowly than single-phase olivine aggregates, as reported by Karato (1989, Tectonophysics, 168, 255-273) (Fig. 3.1-8). Even after 120 hours at 1200°C, there was no significant grain growth, with the grain size only increasing from ~1 µm to ~2 µm. At 1400°C it takes 120 hours for the grain size to increase to ~5 µm. Such long-duration experiments pose many experimental problems. The most significant are a deterioration in temperature and pressure stability and diffusion of water into the Pt capsule. Therefore, these grain growth data should be viewed qualitatively. Figure 3.1-9 shows examples of the microstructure of the samples as obtained by orientation contrast imaging in the SEM. Differential polishing rates caused a relief difference between the two phases, making it possible to distinguish them easily. Unfortunately, the very fine grain size of the samples annealed at 1200°C prevented a detailed microstructural and topological analysis from being carried out. Therefore, relatively coarse-grained samples which had been annealed at 1400°C were studied. Microstructural differences between the two sample types (25% and 50% enstatite) were investigated. The grain size of the mixture containing 25% enstatite is more skewed (more large grains) compared to the mixture containing 50% enstatite, but on average there is no significant difference in grain size between the two samples.

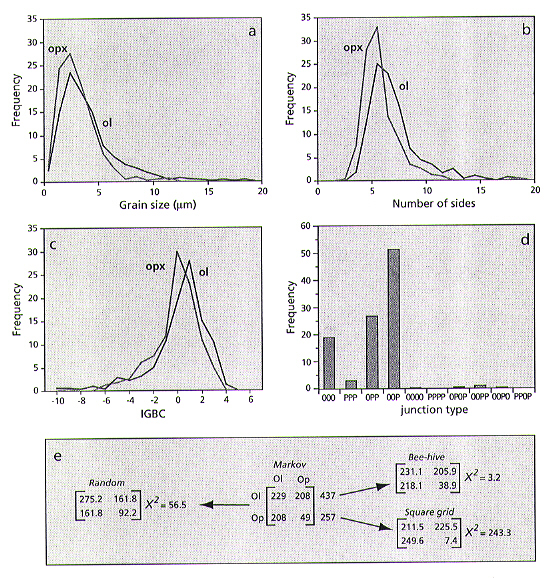

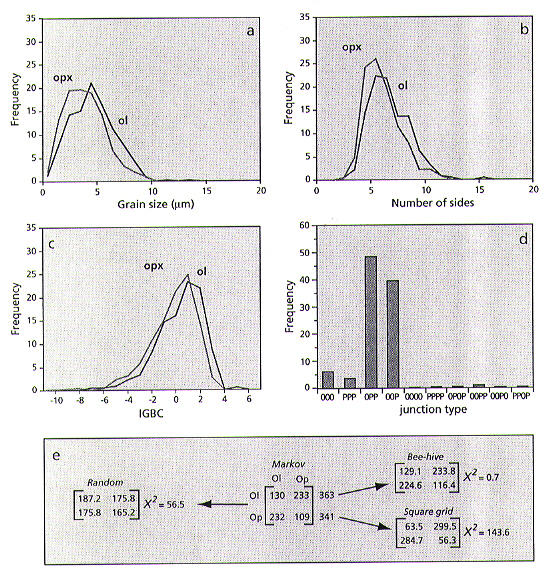

Cahn (1991; Acta Mater. 39, 2189-2199) showed that the stability of grains within a 2-phase mixture depends on the number of faces of the grains, the kind of neighbours and their

|

Fig. 3.1-8: Grain growth kinetics of olivine-enstatite mixtures compared to those of single-phase olivine aggregates (lines) determined by Karato (1989). |

|

|

Fig. 3.1-9: SEM orientation contrast images showing the microstructural differences between mixtures containing 25% enstatite (left) and 50% enstatite (right); 80 hrs, 1400°C. Due to differential polishing rates (using coloidal silica), the ortho-enstatite has a low and the olivine a high relief. This is reversed when turning the page upside down. |

|

distribution in the sample, i.e. it depends on the topology or integrated

grain boundary curvature (IGBC) of the sample. He showed that if a grain

has a negative IGBC it has a driving force to grow, whereas a positive

IGBC will result in a driving force to shrink. This approach has been applied

to the olivine-enstatite mixtures (Fig. 3.1-10, 3.1-11). There are

|

Fig. 3.1-10: Topological parameters of 25% enstatite samples grown at 20 kbar, 1400°C for 80 hrs. (a) Histograms showing grain size distributions in which the similarities between the two phases and the differences between the two mixtures can be seen. (b-d) Histograms showing the distribution of topological parameters: (b) the average number of sides per grain is 5 - 6, (c) many grains have a positive IGBC implying they have a driving force to shrink and (d) only stable tri-junctions occur within the samples. (e) The observed phase distributions, as analysed using Markov chains, differ significantly from randomness (x2 > 4). However, the phase distributions can be described by a bee-hive (6-sided grain) microstructure in which low-energy interphase boundaries are maximised. |

|

Fig. 3.1-11: Topological parameters of 50% enstatite samples grown at 20 kbar, 1400°C for 80 hrs. For (a) - (e) see Fig. 3.1-10. |

only minor differences between the two types of sample. In both cases, only grain tri-junctions are observed, on average grains have 5-6 neighbours and the majority of grains have a positive IGBC. Phase distributions, as analysed using Markov chains, differ significantly from randomness. The observed phase distribution can be modelled by a bee-hive (6-sided grain) microstructure in which low-energy interphase boundaries are maximised. The resultant microstructure then has a minimum-energy phase configuration.

Although there are grains that have a driving force to increase their grain size, many are stable or have a driving force to reduce their size instead. Therefore, grain growth kinetics in these olivine-enstatite mixtures are very sluggish (only few grains will grow) and orders of magnitude lower than that of single-phase olivine.

Tel: +49-(0) 921 55 3700 / 3766, Fax: +49-(0) 921 55 3769, E-mail: bayerisches.geoinstitut(at)uni-bayreuth.de

Previous page

Previous page