The determination of some physical properties such as liquid density and viscosity at high pressures and temperatures, often measured using rising/falling sphere techniques, poses special challenges because of the spatial confinement and reactive environments in high P,T cells. We present a new method of tailoring the density of a composite sphere for use as a probe in high P,T physical property experiments on liquids. The density of the composite sphere, made of an inner high density, metallic spherical core and an outer, low density, refractory spherical shell or mantle, may be chosen by selective assignment of the core/mantle materials and their respective radii.

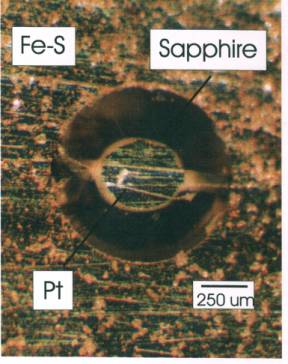

We have devised a simple micro-mechanical method for grinding a concave recess as small as 200µm in diameter in sapphire and ruby hemispheres as small as 500µm in diameter. We have used sapphire and ruby as the mantle material but the technique is applicable to any solid, cohesive material. The method employs a small milling machine (with spindle that can be tilted to an angle of ~30o from vertical) and a shop-made, powered, vertical rotary spindle. A diamond burr is used as the grinding tool and is collet-mounted in the milling machine spindle. With the aid of a microscope and using the x- and y- axis hand wheels of the milling machine for positioning, the z-axis hand wheel is used to make controlled-force contact between the rotating ruby and counter-rotating diamond burr.

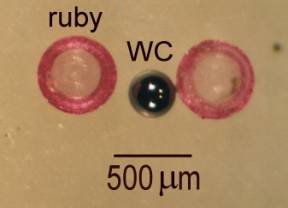

Examples of a composite spheres made with WC or Pt cores and Al2O3 mantles are shown before assembly and after exposure to high P in figures 3.7-4 (a) and (b), respectively. Core spheres are made using an air driven, Bond-type grinder. The two mantle hemispheres are held together using a thin layer of high temperature Al2O3-based cement placed on the opposing rims of the hemispheres.

| (a) | (b) |

|

|

Tel: +49-(0) 921 55 3700 / 3766, Fax: +49-(0) 921 55 3769, E-mail: bayerisches.geoinstitut(at)uni-bayreuth.de

Previous page

Previous page